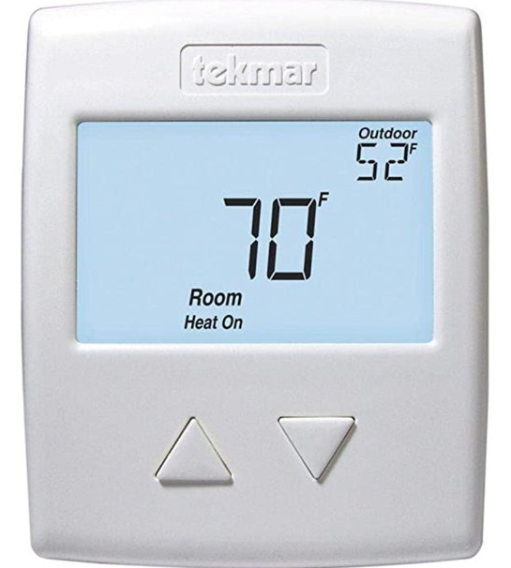

Tekmar 519 Radiant Thermostat

Introduction

The Radiant Thermostat 519 accurately controls the room and/or floor temperature for a hydronic heating zone using Pulse Width Modulation (PWM) technology. Simple up and down buttons and a display with large type make this thermostat easy to read and use. A Slab Sensor 079 is included to measure floor temperature to protect the floor from overheating and enhance comfort. This easy-to-install thermostat is a direct replacement for the tekmar Thermostat 509.

Energy Saving Features: Auto Heating Cycle

Additional Features

- Radiant Floor Heating

- Pulse Width Modulation

- Floor & Air Temperature Control

- Outdoor & Floor Temperature Display

- Backlight

- Freeze Protection

- Includes Slab Sensor 079

Getting Started

Congratulations on the purchase of your new tekmar® thermostat.

This manual will step through the complete installation, programming and sequence of operation for this control. At the back, there are tips for control and system troubleshooting.

Installation

Caution Improper installation and operation of this control could result in damage to the equipment and possibly even personal injury or death. It is your responsibility to ensure that this control is safely installed according to all applicable codes and standards. This electronic control is not intended for use as a primary limit control. Other controls that are intended and certified as safety limits must be placed into the control circuit.

Preparation

Tools Required

- tekmar or jeweller screwdriver

- Phillips head screwdriver

- Wire Stripper

Materials Required

- 18 AWG LVT Solid Wire

- (Low Voltage Connections)

Installation Location

Choose the placement of the thermostats early in the construction process to enable proper wiring during rough-in.

Consider the following:

- Interior Wall.

- Keep dry. Avoid potential leakage onto the control.

- Relative Humidity less than 90%. Non-condensing environment.

- No exposure to extreme temperatures beyond 32-122°F (0-50°C).

- No draft, direct sun, or other cause for inaccurate temperature readings.

- Away from equipment, appliances, or other sources of electrical interference. Easy access for wiring, viewing, and adjusting the display screen. Approximately 5 feet (1.5 m) off the finished floor.

- The maximum length of wire is 500 feet (150 m).

- Strip wire to 3/8” (10 mm) for all terminal connections.

- Use standard 4 conductor, 18 AWG wire.

Removing The Thermostat Base

To remove the thermostat base:

- Locate the tab on the bottom of the thermostat.

- Push the tab with either your thumb or with a screwdriver.

- Lift the thermostat front away from the thermostat’s base.

Mounting The Thermostat

If a single gang box is used:

- Adapter Plate 012 is required (sold separately).

- Feed the wiring through the hole in the adaptor plate and the thermostat base. Fasten the adaptor plate to the gang box.

- Fasten the base of the thermostat to the adaptor plate.

- Terminate wiring to the wiring strip.

- Push the thermostat front onto the thermostat base.

If mounting directly to the wall:

- Drill holes and install the wall anchors.

- Feed the wiring through the large hole in the thermostat base.

- Fasten the thermostat base to the wall using the wood screws to the wall anchors.

- Terminate wiring to the wiring strip.

- Push the thermostat front onto the thermostat base.

Slab Sensor 079 Installation

New Installations

Thin-Set or Thin-Pour Applications

If the floor covering is to be installed over either a thin-set or thin-pour material of sufficient depth, the 079 slab sensor can be placed directly into either the thin-set material or the thin-pour material and covered over. Ensure that the sensor is located in such a position that the attached wire is able to reach a suitable junction location. Splices within the thin-set or thin-pour should be avoided to ensure trouble-free operation. The sensor should be located mid-way between the heating elements to ensure a proper temperature reading.

Thin Floor Coverings (less than 3/8” (10 mm))

If a thin floor covering is to be installed directly to the subfloor, a groove 1/8” (4 mm) wide by 1/16” (2 mm) deep can be cut into the surface of the subfloor to accommodate

the wire for the sensor. Ensure that the sensor is located in such a position that the attached wire is able to reach a suitable junction location. Splices under the floor covering should be avoided to ensure trouble-free operation. A groove 3/16” (5 mm) wide by 3/16” (5 mm) deep by 1-3/4” (45 mm) long should be cut to accommodate the sensor. The sensor should be located mid-way between the heating elements to ensure a proper temperature reading.

Thick Floor Coverings (greater than 3/8” (10 mm))

Thick Floor Coverings (greater than 3/8” (10 mm))

If a thick floor covering is to be installed directly on the subfloor, a groove 1/8” (4 mm) wide by 1/16” (2 mm) deep can be cut into the back of the flooring material to accommodate the wire for the sensor. Ensure that the sensor is located in such a position that the attached wire is able to reach to a suitable junction location.

Splices under the floor covering should be avoided to ensure trouble-free operation. A groove 3/16” (5 mm) wide by 3/16” (5 mm) deep by 1-3/4” (45 mm) long should be cut to accommodate the sensor. The sensor should be located mid-way between the heating elements to ensure a proper temperature reading.

NOTE: If it is not practical to cut a groove in the surface covering, follow the installation method used for thin floor coverings.

Retrofit Installations

Tile Floor Coverings

If a Slab Sensor 079 is to be installed into an existing tile floor with sufficiently large grout lines, the sensor and wire can be installed in one of the grout lines between the tiles. Select a low traffic area of the floor that is mid-way between the heating elements for the sensor location. Ensure that the sensor is located in such a position that the attached wire is able to reach a suitable junction location. Splices within the grout should be avoided to ensure trouble-free operation. Remove the appropriate grout line and place the sensor and wire on the floor. Re-grout the area.

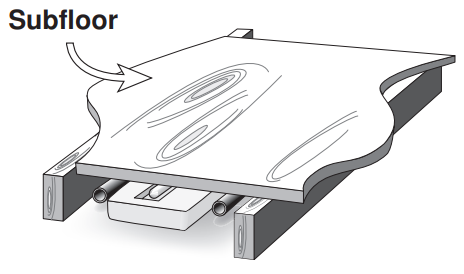

Installing the Sensor to the Bottom of a Subfloor

If the sensor is to be installed to the bottom of a subfloor, cut a piece of 1” (25 mm) thick rigid insulation into a 6” (150 mm) by 6” (150 mm) square. A groove 3/16” (5 mm) wide by 3/16” (5 mm) deep by 1-3/4” (45 mm) long should be cut into the insulation to accommodate the sensor. Place the sensor in the groove and sandwich the sensor between the insulation and the subfloor. Use a suitable fastening method to affix the insulation to the subfloor.

Slab Sensor 079 Wiring

Slab Sensor 079 Wiring

Caution: Do not run sensor wires parallel to telephone or power cables. If the sensor wires are located in an area with strong sources of electromagnetic interference,

shielded cable or twisted pair should be used or the wires can be run in a grounded metal conduit.

The Slab Sensor 079 is supplied with 10’ (3 m) of cable. If a longer length is required, 24 AWG or larger wire can be spliced onto the two wires from the sensor. The splices should be properly soldered and protected in an accessible junction box. Follow the sensor testing instructions given in this brochure and then connect the wires to the control.

Slab Sensor 079 Testing

A good quality test meter capable of measuring up to 5,000 kΩ (1 kΩ = 1000Ω) is required to measure the sensor resistance. In addition to this, the actual temperature must be measured with either a good quality digital thermometer, or if a thermometer is not available, a second sensor can be placed alongside the one to be tested and the readings compared.

First, measure the room temperature using the thermometer. Disconnect the Sen and Com wires from the thermostat. Using an electrical meter, measure the resistance of the

Sen and Com wires at the thermostat location. Using the temperature versus resistance table, estimate the temperature measured by the sensor. The sensor measurement and

thermometer readings should be close. If the test meter reads a very high resistance, there may be a broken wire, a poor wiring connection or a defective sensor. If the

resistance is very low, the wiring may be shorted, there may be moisture in the sensor or the sensor may be defective. To test for a defective sensor, measure the resistance

directly at the sensor location. Once the test has been completed, reconnect the Sen and Com wires to the thermostat.

Do not apply voltage to the temperature sensor terminals at any time as damage to the sensor may result.

Temperature vs. Resistance Table

| Temperature | Resistance | |

| °F | °C | Ω |

| -50 | -46 | 490,813 |

| -45 | -43 | 405,710 |

| -40 | -40 | 336,606 |

| -35 | -37 | 280,279 |

| -30 | -34 | 234,196 |

| -25 | -32 | 196,358 |

| -20 | -29 | 165,180 |

| -15 | -26 | 139,402 |

| -10 | -23 | 118,018 |

| -5 | -21 | 100,221 |

| 0 | -18 | 85,362 |

| 5 | -15 | 72,918 |

| 10 | -12 | 62,465 |

| 15 | -9 | 53,658 |

| 20 | -7 | 46,218 |

| 25 | -4 | 39,913 |

| 30 | -1 | 34,558 |

| 35 | 2 | 29,996 |

| 40 | 4 | 26,099 |

| 45 | 7 | 22,763 |

| 50 | 10 | 19,900 |

| 55 | 13 | 17,436 |

| 60 | 16 | 15,311 |

| 65 | 18 | 13,474 |

| 70 | 21 | 11,883 |

| 75 | 24 | 10,501 |

| 80 | 27 | 9,299 |

| 85 | 29 | 8,250 |

| 90 | 32 | 7,334 |

| 95 | 35 | 6,532 |

| 100 | 38 | 5,828 |

| 105 | 41 | 5,210 |

| 110 | 43 | 4,665 |

| 115 | 46 | 4,184 |

| 120 | 49 | 3,760 |

| 125 | 52 | 3,383 |

| 130 | 54 | 3,050 |

| 135 | 57 | 2,754 |

| 140 | 60 | 2,490 |

| 145 | 63 | 2,255 |

| 150 | 66 | 2,045 |

| 155 | 68 | 1,857 |

| 160 | 71 | 1,689 |

| 165 | 74 | 1,538 |

| 170 | 77 | 1,403 |

| 175 | 79 | 1,281 |

| 180 | 82 | 1,172 |

| 185 | 85 | 1,073 |

| 190 | 88 | 983 |

| 195 | 91 | 903 |

| 200 | 93 | 829 |

| 205 | 96 | 763 |

| 210 | 99 | 703 |

| 215 | 102 | 648 |

| 220 | 104 | 598 |

| 225 | 107 | 553 |

Thermostat Wiring

Zone Valve

Wiring Center 315 or 316

Relay 003

Switching Relay

Testing the Thermostat Wiring

Testing the Power

If the thermostat display turns on, this indicates that the thermostat is operating correctly and there are no electrical issues. In the event that the display is permanently off:

- Remove the thermostat front.

- Use an electrical meter to measure voltage between the R and C wiring terminals.

For AC power supplies the voltage should measure between 10 to 30 V (ac). For DC power supplies the voltage should measure between 10 to 30 V (dc). - If the voltage on the R and C wire terminations is continuous and the thermostat display is not on, the thermostat may have a fault. Contact your tekmar sales

a representative for assistance.

If the thermostat display initially powers on but later shuts off intermittently, there may be a short circuit from the W wire to the ground, or the power supply is too small to

power the load.

Testing the Heat Zone Output Wiring

- Touch the△button and set the heating temperature above the current room temperature. Make sure the display does not flash “Max” if using a floor sensor.

- When the “Heat On” symbol appears on the display, use an electrical meter to check for voltage on the W and C wires connected to the zone valve, wiring center, relay, or switching relay. The electrical meter should read 10 to 30 V (ac) or (dc).

- If the W and C wires have voltage, check the zone valve, wiring center, relay or pump to determine if the heating device is operating correctly.

User Interface

Home Screen

Symbols Description

|

HEAT ON The heat is turned on. |

|

MIN The floor is at or below the floor minimum temperature. |

| MODE OFF The heating system is off. |

MAX The floor has reached the floor maximum temperature. |

||

| WARNING SYMBOL Indicates an error is present. |

AWAY Operating at the away temperature. |

Sequence of Operation

Heating Operation

Push the △or ▽ button to select a preferred temperature setting. The Heat On symbol is shown on the display when the thermostat is heating. The heat can cycle on and off

within +/- 1.5°F (1°C) of the temperature setting.

The floor and air heating can be shut off by holding the▽ button until Set Room is Off. To resume heating when the Mode is Off, press the △button to navigate to the Mode

setting, then press the △button to select Mode Heat. The thermostat will resume heating at the last previously set temperature.

The away feature saves energy by heating to a lower temperature while you are away.

To activate Away, short the Away and Com wiring terminals together.

Air Temperature Only

If there is only an air temperature sensor (no floor sensor), the thermostat operates to control your desired air temperature.

Floor Temperature Only

If the air sensor has been disabled, the thermostat will only maintain floor temperature and ignore air temperature. This operation is recommended for areas such as bathrooms

to ensure that tile floors are warm to the touch.

Floor and Air Temperature

If the air sensor is turned on and a floor sensor is connected, the thermostat will maintain the desired air temperature as well as a minimum floor temperature.

This operation is recommended for areas with large windows that allow the sun to shine into a room and keep it warm without the need for heat. This can allow the floors to cool off during the afternoon. When the sun goes down, it can take a long time for the floors to get warm again. This may cause the room to cool off too much in the early evening. A floor minimum setting can help with this condition by maintaining a floor minimum temperature. Keep in mind the floor minimum temperature will override the

air temperature, and if set too high, may overheat the room.

This operation is also recommended for rooms with hardwood floors. Setting floor minimum and maximum temperatures is a way of enhancing the comfort of the living space while protecting floor coverings.

Programmable Settings

| Setting | Display |

| User settings. Press the△ and ▽ buttons together for 3 seconds to enter andadvance to the next setting. | |

| MODE Select heat or off. |  |

| Range: HEAT, OFF | Default: HEAT |

| UNITS Select the temperature units. |  |

| Range: °F or °C | Default: °F |

| LIGHT Select when the display back light should operate. Auto operates the backlight for 30seconds after a keystroke. |

|

| Range: OFF, AUTO, ON | Default: AUTO |

| SET FLOOR Set the floor minimum temperature. Available when an auxiliary floor sensor is connected and the built-in room sensor is on. |  |

| Range: OFF, 40 to 122°F (4.5 to 50.0°C) | Default: 72°F (22.0°C) |

| TYPE Device Typenumber. Hold the a, button △ to view the software version. |  |

| ESCAPE Release the △ and▽buttons to return to the home screen.△▽ |  |

| Installer settings. Press the △ and▽ buttons together for 5 more seconds. | |

| AUXILIARY SENSOR Select the type of auxiliary sensor. Available when an auxiliary sensor is automatically detected. |

|

| Range: NONE = no auxiliary sensor, ROOM = Indoor Sensor, FLOR = Slab Sensor, OUT = Outdoor Sensor | Default: OFF |

| ROOM SENSOR Select if the built-in room temperature sensor is on or off. The built-in room sensor can only be disabled when an auxiliary room or slab sensor is connected. |

|

| Range: ON or OFF | Default: ON |

| SET FLOOR MAXIMUM Set the floor maximum temperature in order to protect the floor covering. Suggested settings: Tile = 90°F (32°C), Wood Floor = 85°F (29°C) |  |

| Range: 40 to 122°F (4.5 to 50.0°C) OFF | Default 85°F (29.5°C) |

| SET AWAY Set the away temperature. | |

| Range: OFF, 40 to 122°F (4.5 to 35.0°C) | Default: 50°F (10.0°C) |

| ESCAPE Release the △ and▽ buttons to return to the home screen. |  |

Troubleshooting

Error Messages

| Error Message | Description |

|

SETUP MENU SAVE ERRORThe thermostat failed to read the Programmable Settings from memory and has reloaded the factory default settings. The thermostat stops normal operation until all Programmable Settings are checked except to provide freeze protection. |

| ROOM SENSOR OPEN CIRCUIT ERRORThe built-in air temperature sensor has an open circuit fault. Do not confuse this error with the auxiliary room sensor short circuit error.

This error cannot be field repaired. Contact your wholesaler or tekmar sales representative for details on repair procedures. |

|

| ROOM SENSOR SHORT CIRCUIT ERRORThe built-in air temperature sensor has a short circuit fault. Do not confuse this error with the auxiliary room sensor short circuit error.

This error cannot be field repaired. Contact your wholesaler or tekmar sales representative for details on repair procedures. |

|

| AUXILIARY SENSOR OPEN CIRCUIT ERRORThe auxiliary sensor has an open circuit. Check for loose or damaged wires. Locate and repair the problem as described in the Sensor Testing section of this brochure. The error clears after the auxiliary sensor fault is corrected. If the auxiliary sensor was intentionally removed, power the thermostat down and up to clear the error. | |

| AUXILIARY SENSOR SHORT CIRCUIT ERRORThe auxiliary sensor has a short circuit. Check for damaged wires. Locate and repair the problem as described in the Sensor Testing section of this brochure. The error clears after the auxiliary sensor fault is corrected. |

Frequently Asked Questions

| Symptom | Look for… | Corrective Action |

| Display powering on and off. | Measure voltage at wiring terminals R and C. | The power supply transformer may have limited VA capacity. A transformer with a larger VA rating is recommended. |

| The thermostat does not heat. | Mode Off | The thermostat must be in Mode Heat in order to provide heating. |

Technical Data

| Radiant Thermostat 519 One Stage Heat | |

| Literature | 519_C, 519_D, 519_Q, 519_U |

| Control | Microprocessor control. This is not a safety (limit) control |

| Packaged weight | 0.6 lb. (290 g) |

| Dimensions | 3-11/16″ H x 3″ W x 15/16″ D (94 x 76 x 24 mm) |

| Enclosure | White PVC plastic, NEMA Type 1 |

| Approvals | Meets Class B: ICES & FCC Part 15 |

| Ambient conditions | Indoor use only, 32 to 122°F (0 to 50°C), RH 590% non-condensing |

| Power supply | 10 to 30 V (ac/dc), 50/60 Hz, 1.8 VA standby, 56 VA max fully loaded, Class 2 |

| Relay | 30V (ac/dc) 2 A, Class 2 circuits |

| Sensor | NTC thermistor, 10 kO @ 77°F (25°C ±0.2°C) 8=3892 |

| — Included | Slab Sensor 079 |

| — Optional | tekmar type # 070, 072, 073, 076, 077, 079, 084 |

| Slab Sensor 079 10′ (3 m) wire | |

| Dimensions | 3/16″ OD x 1-1/2″ (5 OD x 38 mm) |

| Enclosure | 316 stainless steel, 10′ (3 m) 24 AWG, 300 volt PVC insulated Zipcord |

| Operating range | -58 to 140°F (-50 to 60°C) |

| Sensor | NTC thermistor, 10 kO @ 77°F (25°C ±0.2°C) 8=3892 |

Limited Warranty and Product Return Procedure

Limited Warranty The liability of tekmar under this warranty is limited. The Purchaser, by taking receipt of any tekmar product (“Product”), acknowledges the terms of the Limited Warranty in effect at the time of such Product sale and acknowledges that it has read and understands same.

The tekmar Limited Warranty to the Purchaser on the Products sold hereunder is a manufacturer’s pass-through warranty which the Purchaser is authorized to pass through to its customers. Under the Limited Warranty, each tekmar Product is warranted against defects in workmanship and materials if the Product is installed and used in compliance with tekmar’s instructions, ordinary wear and tear excepted. The pass-through warranty period is for a period of twenty-four (24) months from the production date if the Product is not installed during that period, or twelve (12) months from the documented date of installation if installed within twenty-four (24) months from the production date.

The liability of tekmar under the Limited Warranty shall be limited to, at tekmar’s sole discretion: the cost of parts and labor provided by tekmar to repair defects in materials and/or workmanship of the defective product; or to the exchange of the defective product for a warranty replacement product; or to the granting of credit limited to the original cost of the defective product, and such repair, exchange or credit shall be the sole remedy available from tekmar, and, without limiting the foregoing in any way, tekmar is not responsible, in contract, tort or strict product liability, for any other losses, costs, expenses, inconveniences, or damages, whether direct, indirect, special, secondary, incidental or consequential, arising from ownership or use of the product, or from defects in workmanship or materials, including any liability for fundamental breach of contract.

The pass-through Limited Warranty applies only to those defective Products returned to tekmar during the warranty period. This Limited Warranty does not cover the cost of the parts or labor to remove or transport the defective Product, or to reinstall the repaired or replacement Product, all such costs and expenses being subject to the Purchaser’s agreement and warranty with its customers.

Any representations or warranties about the Products made by Purchaser to its customers which are different from or in excess of the tekmar Limited Warranty are the Purchaser’s sole responsibility and obligation. Purchaser shall indemnify and hold tekmar harmless from and against any and all claims, liabilities, and damages of any kind or nature which arise out of or are related to any such representations or warranties by Purchaser to its customers.

The pass-through Limited Warranty does not apply if the returned Product has been damaged by negligence by persons other than tekmar, accident, fire, Act of God, abuse or misuse; or has been damaged by modifications, alterations or attachments made subsequent to purchase which have not been authorized by tekmar; or if the Product was not installed in compliance with tekmar’s instructions and/or the local codes and ordinances; or if due to defective installation of the Product; or if the Product was not used in compliance with tekmar’s instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, WHICH THE GOVERNING LAW ALLOWS PARTIES TO CONTRACTUALLY EXCLUDE, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, DURABILITY OR DESCRIPTION OF THE PRODUCT, ITS NON-INFRINGEMENT OF ANY RELEVANT PATENTS OR TRADEMARKS, AND ITS COMPLIANCE WITH OR NON-VIOLATION OF ANY APPLICABLE ENVIRONMENTAL, HEALTH OR SAFETY LEGISLATION; THE TERM OF ANY OTHER WARRANTY NOT HEREBY CONTRACTUALLY EXCLUDED IS LIMITED SUCH THAT IT SHALL NOT EXTEND BEYOND TWENTY-FOUR (24) MONTHS FROM THE PRODUCTION DATE TO THE EXTENT THAT SUCH LIMITATION IS ALLOWED BY THE GOVERNING LAW.

Product Warranty Return Procedure All Products that are believed to have defects in workmanship or materials must be returned, together with a written description of the defect, to the tekmar Representative assigned to the territory in which such Product is located. If tekmar receives an inquiry from someone other than a tekmar Representative, including an inquiry from Purchaser (if not a tekmar Representative) or Purchaser’s customers, regarding a potential warranty claim, tekmar’s sole obligation shall be to provide the address and other contact information regarding the appropriate Representative.

Product design, software and literature are Copyright ©2013 by tekmar Control Systems Ltd., A Watts Water Technologies Company. Head Offi ce: 5100 Silver Star Road, Vernon, B.C. Canada V1B 3K4, 250-545-7749, Fax. 250-545-0650 Web Site: www.tekmarControls.com

Reference

Tekmar 519 Radiant Thermostat Installation and Operation Manual

Tekmar 519 Radiant Thermostat Installation and Operation Manual

Other manuals:

Tekmar 519 Radiant Thermostat Quick Set-up Guide

Tekmar 519 Radiant Thermostat User Manual

Tekmar 519 Radiant Thermostat Specification Sheet

Tekmar 519 Radiant Thermostat Installation and Operation Manual

Leave a Reply